Manufacturing in India: MAKE IN INDIA

- AAKASHDEEP AGARWALA

- ABHISHEK GOYAL

- HARSH PARMAR

- SOURAB

Abstract

The research assesses the Indian Manufacturing Sector and provides an insight into the ups and down it has witnessed. Since India’s independence, the Indian Manufacturing Sector has witnessed a steady growth, but not up to its full potential. Currently, the highest contributor (% wise) of Indian economy is Services Sector. Why has Indian Manufacturing Sector not been a major contributor? The research identifies the aspects due to which India’s Industrial sector suffer. To revive this sector, India’s new government has taken the initiative of “Make in India”, which tries to rectify the shortcomings in the Industrial Sector. The research also tries to observe the best manufacturing practices followed globally by aggressively developing and developed economies, which can be feasibly incorporated in India.

TABLE OF CONTENTS

|

Introduction |

1 |

|

Literature Review |

2 |

|

Conceptual Framework |

4 |

|

Research Methodology |

5 |

|

Research Findings |

6 |

|

Conclusion and Limitations |

11 |

|

References |

12 |

Introduction

Historically, India has always been an agricultural nation. The major share of GDP was from this sector till the early 1950s and 60s. Down the line, its share began to decline and service sector started to emerge. Today, service sector plays a prominent role in the economy of India. On the other hand, industrial sector has been growing right from the beginning but the growth is not as consistent as that of service sector. This raises the question that India, in spite of having a huge population and demand, lags behind in the manufacturing sector. As clearly seen from the graph, the representation of each sector in the GDP of the country; manufacturing doesn’t contribute heavily.

Figure 1: Shares of Agriculture, Industry and Services in India

Agricultural sector employs major workforce in India, but since it doesn’t require any specialization or expertise in doing that job it yields very low output. Agriculture contributes to about 17.4% of GDP and it employs about 49% of workforce. Services cannot include high workforce since it requires a specialized expertise in a specific field and due to various reasons, everyone doesn’t possess it. Manufacturing is in midway of agriculture and services and for a country with such high demographic dividend, it is manufacturing which can drive the economy and can employee labour force in huge number.

Thus, the research intends to identify the issues that hinder the role of manufacturing in the Indian Economy. The study will help quantify the factors and better judge their influence on each sector of the country. Furthermore, the study analysed the Make in India campaign’s offering to revive the industries in India.

Literature Review

Emerging economies have witnessed reliance on manufacturing sector and export of manufactured goods. India has also given manufacturing its due importance since mid – 1980s. But last two decades have witnessed growth from services sector and not manufacturing sector. Despite focussing on manufacturing sector in India, India did not excel in it as much as its counterparts like China. The reason behind the same can be attributed to numerous reasons. Firstly, the huge presence of unorganized sector, the policies stress on improving performance of registered manufacturing sector and unorganized sector remain neglected. Secondly, infrastructural bottlenecks like lack of power supply, road networks tend to be disadvantageous for Indian Manufacturers. This way the costs of production goes up; eventually exporting uncompetitive manufactured goods to foreign markets. Lastly, archaic land acquisition laws tend to thwart the dynamism demanded by manufacturing sector. Also, the discord between centre and state tends to delay the process, affecting the sector adversely.

Get Help With Your Essay

If you need assistance with writing your essay, our professional essay writing service is here to help!

Keeping all the above factors in mind, Make in India campaign looks optimistic. It makes sure that the issues in previous attempts of reviving manufacturing sector are not repeated. For this, the Make in India initiative looks to revive Indian Manufacturing sector holistically. It gives importance to SME’s(Small and Medium Size Enterprises), better infrastructure and better governance so as to have an inclusive growth. The contribution of Manufacturing Sector was consecutively 16% towards our GDP from 1980 to 1990 but the share had been 13% in the year 2013.

Consecutively the contribution of the service sector was 40% in the year 1980 which rose to 57% in 2013. The economy had significant growth post liberalization. Ray (2013) tried to understand whether the growth in the service sector had any influence on the growth of the manufacturing sector. For this he used the data from 1970-71 to 2009-10. He noted, “The results of co-integration test show that there is no long-term relationship between the growths in the two sectors.”

There are many issues plaguing the Indian economy where one of them happens to be corruption. An extensive work was done on this by Kato and Sato (2014) where they tried to investigate how corruption impacts the performance of manufacturing sector at the state level in India. The conclusion which they arrived at was that there is a reduction in gross value added per worker and total factor productivity. The paper also showed that the effects of corruption are more relevant in industries with smaller average firm size.

According to Kalirajan and Bhide(2004), Manufacturing was an engine of growth in the 1970s and 80s but this speed slowed down since the 1991 economic reform. According to them, the output growth of the manufacturing sector of India in the post reform period was input-driven rather than technology or efficiency driven.

Institution changes also played a large role in the manufacturing productivity, Pandey and Dong(2009) did a study on this vis-à-vis China where it was noted that the productivity of manufacturing industries in China improved rapidly between 1998-2003 in relation to India. The most important change noticed in China which wasn’t observed in India was in the fag end of the 1990s, when there was an enormous wave of ownership restructuring as the communist government of China had formally endorsed private property rights. To counter the long standing predicament of redundancy of labour in the public sector, which was about 30% of Total Factor Productivity, a large scale labour economising program was launched.

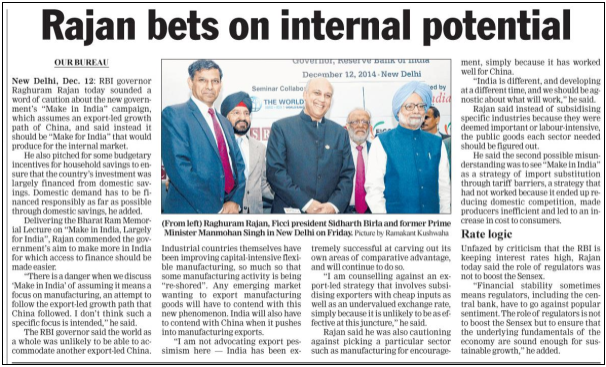

Figure 2

Raghuram Rajan has provided an insightful opinion, that China’s export – driven Manufacturing growth should not be focus of India. Rather, according to Rajan, catering to the internal domestic needs should be a priority, as the current volatile market trend may or may not respond positively to export – oriented industry. Thus, by focussing on inclusive growth, India should produce for internal market; which should be the government’s focus.

Based on the theories propounded, the implications and findings showed a solid framework about the Manufacturing Sector in India being not so independent but dependent on myriad factors. The study analysed these factors and present how the Government actually arrived at branding this as “Make in India”. Also, what all policies that are new or have been used in other economies can accelerate the manufacturing sector in India.

Conceptual Framework

Upon closer introspection, there are numerous issues acting as bottlenecks for Indian Manufacturing Sector. The factors which are considered are as follows:

- Is the infrastructure and power in the country conducive enough to cater to the industries?

- Does the work force possess right skills?

- Are the land acquisition laws business-friendly?

- Is the technology deployed in processes at par with Indian counterparts?

- Are the FDI norms too stringent?

- Are the products that are “Made in India”, competitive in global markets?

- How is the ease-of-business environment in the country?

Research Methodology

The research methodology employed is Applied Research Methodology. Secondary data would be used by us to carry out our research. The data would be collected from secondary data sources such as:

- World Bank

- United Nations Development Programme

- Central Intelligence Agency

- International Monetary Fund

- Central Statistical Organization

- Reserve Bank of India

- Finance Ministry, Government of India

- Interviews and Excerpts of Industry Experts

- Census of India, NSSO, India

- Newspaper Articles

From the above sources, the study analysed the shortcomings prevalent in the Indian Manufacturing sector. The indicators which will be collected from these sources are labour utilization, labour productivity, per capita income, ease-of-business rankings, unemployment rate etc. With these parameters, the research would be assessing how the Make in India Campaign by the new government in India would affect the Indian Economy.

Research Findings

Currently India is placed at 134th rank compared to last year’s 131st in the “Ease of doing business Index” which is lower than its BRICS counterparts.

Land Acquisition happens to be a critical issue as most of the landowners are wary of selling their land because of potential future appreciation of price and lack of transparency in benchmarks. As per a survey conducted by KPMG-CII, on an average the time to acquire land is 14 months and the number of departments to be visited makes the land acquisition much more complex.

The respondents of this survey identified certain key initiatives taken in certain states such as CARD in AP, SIR, GIDC and e-Dhara Bhulekh in Gujarat, KAVERI and KIADB in Karnataka etc. In Tamil Nadu an industrial cluster was formed to take care of such hindrances. The critical enablers noticed in these initiatives were technology, regulatory bodies and policies.

The research recommendation would be to simplify the land acquisition process as well as the bureaucratic hurdles. E-procedures can help improve all these since it curbs unethical practices and streamlines the process flow. As observed, promoting industrial clusters where state governments can be included in making the required policy where the cluster may highlight the specialisation factor of the state concerned. The Right to Fair Compensation and Transparency in Land Acquisition, Rehabilitation and Resettlement Act, 2013 was a major concern for the landowners as they felt that the compensation received under the guidelines of this act was less than what the market rate was fetching them. Instead of actually buying the land from them it could be leased out from them on a long term basis.

There are various approvals required in starting a business in India i.e. Registration, Tax Approvals, Environment Clearance, Land Procurement, Construction Permits & NOCs, Water Connection, Power Connection, Quality Certificates etc. A large chunk of the respondents rated land approvals as the major hindrance in starting a business.

There was a major requirement for a single window clearance. The major initiatives taken state-wise were “The Single-Window Clearance Act, AP and Rajasthan”, “Online Building Plan Approval System, Karnataka”, “One-Stop Centre, Punjab”, “Single Window Clearance Mechanism, Orissa” etc.

But it is not just approvals but even the infrastructure is a key concern, be it obtaining power connections or water sewerage approvals.

The other concerns were inconsistent labour laws and corruption. The National Manufacturing Policy aims to create specific “National Investment and Manufacturing Zones (NIMZs)” with flexible labour laws and stable business regulations.

The recommendations would be to implement a “Bizfile” kind of system, like the one that is prevalent in Singapore where the filing and information retrieval takes place on an internet based online portal which enables individuals to register businesses on their own. The Government should improve the single window clearance, relax environment related clearances, introduce a flexible labour policy, improve labour skill development and channelize NREGA funds for skill building and enhancing employability.

Figure 3

Figure 3

High tax rates emerged as a major obstacle for companies doing business in India.

The bellwether of Indian economy happens to be the IT industry and a general perception is to give a tax holiday to this industry to continue its growth trajectory. The complex taxation regime with respect to use of passive infrastructure, management services needs to be simplified. With respect to infrastructure the tax incentive regime should be investment linked rather than profit-linked.

Major initiatives taken by different states are AASTHI in Karnataka, “Electronic registration, filling and payment of state VAT in AP” etc.

The recommendations are to ease the payment of taxes by bringing in online services, providing tax incentives to units located in special economic zones, industrial areas etc., also bringing in structural reforms such as Direct Tax Code, Goods and Services Tax, easing transfer pricing, implementing a comprehensive GAAR.

Judiciary: Korea is a pioneer when it comes to using electronic features to streamline court processes, India should also adopt a similar platform.

But the main recommendation is to update certain antiquated laws such as Indian Contract Act, 1872, Indian Penal Code, 1860 etc. and doing away with the Wealth Tax Act, 1957.

As it is known, the Cobb Douglas Production function and how the Growth Accounting Equation is derived from it;

The Growth Accounting Equation being:

Where:-

,

,

,

,

|

Overall |

Avg. Annual Growth rate |

||||||

|

1961-2004 |

1961-1970 |

1971-1980 |

1981-1990 |

1991-1995 |

1996-2000 |

2001-2004 |

|

|

GDP (Y) |

7.2 times |

4.20% |

3.40% |

7.20% |

5.60% |

6.60% |

7% |

|

Labor (L) |

2.4 times |

0.80% |

3.50% |

3% |

1.20% |

1.90% |

2% |

|

Output per worker |

3 times |

3.20% |

-0.10% |

3.20% |

4.20% |

4.30% |

4.70% |

Source- http://mpra.ub.uni-muenchen.de/10316/1/MPRA_paper_10316.pdf

As can be observed see that labour capital is with us as the increase in the labour productivity from 1961-2004 has been approximately 2.4 time but what is required is capital, be it in the form of Foreign Direct Investment i.e. FDI or in the form of domestic production of capital. Hence the concept of Make in India arises. Regarding Total Factor Productivity (TFP) it is known that it is more concerned about how labour and capital interact with each other.

Figure 4

Source- http://rbidocs.rbi.org.in/rdocs/PublicationReport/Pdfs/EPGIKLEMS110614.pdf

Conclusion and Limitations

Figure 5

Source- http://www.nehu.ac.in/Journals/NEHUJournalJan_June2014_Art6.pdf

As can be seen that the Total Factor Productivity increased from a negative 0.14 percent to 2.18 percent. Total Factor Productivity happens to be the most important factor for “Make in India” because this is what will drive the Indian Manufacturing sector more importantly than policy reforms or taxation regime or even other incentives. A worker in Sweden is more efficient than one in Pakistan because the knowledge is more in case of the former; this is because of Total Factor Productivity. Hence the study aims that the policy makers should concentrate on this first as this is what will drive up the economy.

Find Out How UKEssays.com Can Help You!

Our academic experts are ready and waiting to assist with any writing project you may have. From simple essay plans, through to full dissertations, you can guarantee we have a service perfectly matched to your needs.

View our academic writing services

The major limitation is that too much emphasis is being laid on “Make in India”, but the fact is that the model which worked for China may not work for India as they were following a path of export oriented manufacturing but in India what is required is manufacturing for domestic consumption, but the world may not be ready for another China due to the global economy still being weak.

References

- http://economictimes.indiatimes.com/

- http://www.moneycontrol.com/video/current-affairs/makeindia-to-develop-nation-as-mfg-superpower-modi_1188340.html

- http://www.livemint.com/

- http://www.bloomberg.com/video/narendra-modi-kicks-off-make-in-india-campaign-w4tvodLkS1uOYgJQSWPCpQ.html

- http://profit.ndtv.com/videos/news/video-make-in-india-to-be-a-growth-driver-chanda-kochhar-339387

- https://www.cia.gov/library/publications/the-world-factbook/fields/2048.html

- http://data.worldbank.org/indicator/SL.TLF.TOTL.IN

- https://www.cia.gov/library/publications/the-world-factbook/fields/2012.html

- http://www.kpmg.com/IN/en/IssuesAndInsights/ArticlesPublications/Documents/KPMG-CII-Ease-of-doing-business-in-India.pdf

- http://epaper.telegraphindia.com/details/124132-18144562.html

- Ray, Sougata. IUP Journal of Applied Economics. Jan2013, Vol. 12 Issue 1, p68-76. 9p. 3 Charts. , Database: Business Source Complete

- Kato, Atsushi; Sato, Takahiro. Economics of Governance. May2014, Vol. 15 Issue 2, p155-178. 24p. DOI: 10.1007/s10101-014-0140-y. , Database: Business Source Complete

- Kalirajan, K., & Bhide, S. (2004). The Post-reform Performance of the Manufacturing Sector in India. Asian Economic Papers, 3(2), 126-157. doi:10.1162/1535351044193367

- Pandey, M., & Dong, X. (2009). Manufacturing productivity in China and India: The role of institutional changes. China Economic Review (1043951X), 20(4), 754-766. doi:10.1016/j.chieco.2009.05.002

1 | Page

Cite This Work

To export a reference to this article please select a referencing style below: